Coating & Shielding Capabilities

Pretreatment & Surface Prep

We apply a variety of pretreatments to ensure optimal adhesion and coating performance:

- Sandblasting (Aluminum Oxide / Glass Bead)

- Solvent Cleaning

- Wash Priming

- Sealing & Bonding Primers

Paint Systems

We offer a full range of paints and coating types, with custom gloss, texture, and color options:

- Lacquer Paints

- 2K urethane paints – Available in smooth to heavily textured finishes, from low to high gloss

- Waterborne Paints – Eco-friendly, scuff-resistant, and smooth-finishing coatings

Colors can be matched to samples or Pantone/Federal Standard guides. Texture and color chips available upon request.

EMI/RFI Shielding

Protect your product from electromagnetic and radio frequency interference—or prevent it from emitting disruptive signals. We offer conductive coatings including:

- Nickel

- Copper

- Silver

- Copper-Coated Silver

Ecoplate™ Metal Shielding

Our exclusive metal shielding technology provides a solid, reliable EMI barrier with environmental benefits and exceptional part coverage.

Military-Spec & CARC Coatings

We apply mil-spec primers and CARC (Chemical Agent Resistant Coating) in both 2K and waterborne systems for military and defense-grade durability.

Value-Added Operations

Fully integrated post-processing and assembly support to streamline your workflow.

Minor Assembly

Pad Printing / Silk Screening

Gluing

Ultrasonic Welding

Heat Staking

Flow/Fill Painting

Part Stamping

Customized Packaging

Local Delivery

Complex and Custom Masking

Hard Mask Fabrication (In-House)

Screws, Plugs, Dots

Custom Fixtures

Complex Tape Masks

Quality Commitment

At Florida Custom Mold, we're committed to continuously improving our ability to meet your product requirements, delivery timelines, and overall satisfaction.

To ensure each part meets exact specifications, we perform thorough testing and quality checks, including:

Visual Inspection

Wet Film Thickness

Resistance Testing

Wipe Tests

ASTM Crosshatch Adhesion Tests

Dimensional Verification

Have unique testing requirements? We're happy to integrate your custom protocols into our inspection plans.

How We Work

Here's how we turn your ideas into precision parts

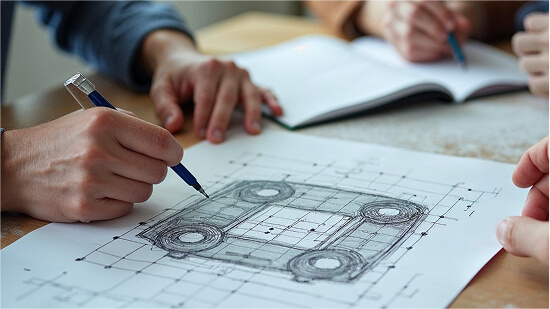

Consult & Design

We start by listening to your needs. Our team collaborates with you to design custom molds—single or multi-cavity—using advanced tools, ensuring every detail fits your vision.

Why Us? Personalized attention from our dedicated crew sets the stage for success.

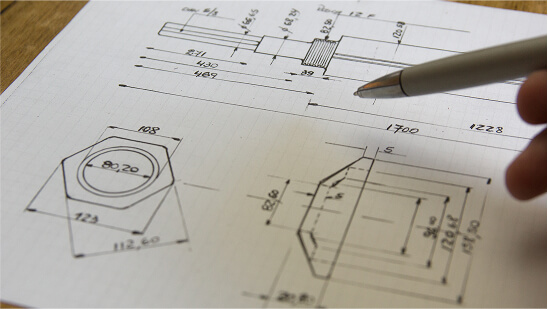

Build with Precision

Using state-of-the-art CNC machining and EDM tech, we craft your molds in-house. This means faster builds, tighter quality control, and parts that perform perfectly.

Why Us? Our cutting-edge equipment and expertise deliver unmatched precision and speed.

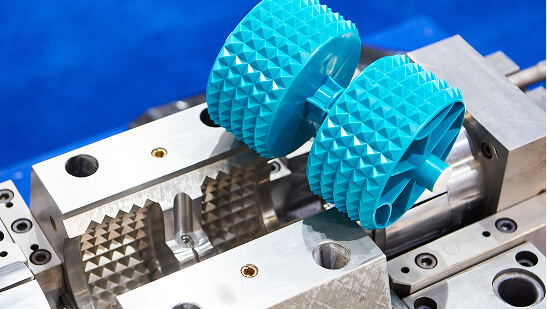

Mold & Produce

We bring your mold to life with our injection molding process, creating high-quality plastic parts tailored to your specs—whether it's one prototype or thousands of pieces.

Why Us? End-to-end service keeps everything seamless and on time.

Support & Refine

Need tweaks or repairs? We've got you covered with in-house mold maintenance and ongoing support to keep your production running smoothly.

Why Us? We go beyond delivery, ensuring your success long-term.

In summary, creating a high-quality mold isn't just about cutting steel—it's about precision, efficiency, and problem-solving. At Florida Custom Mold, the journey begins with expert engineering that transforms your idea into a functional design. Our team leverages decades of experience to craft molds that balance durability, speed, and cost-effectiveness. Whether you need a prototype to test your concept or a full-scale production mold, we tailor each solution to your unique needs. Advanced mold-making techniques ensure seamless functionality, while rigorous testing guarantees a reliable end product. From initial concept to final production, we prioritize efficiency and quality, so your parts come out flawless every time.

Let's Discuss Your Project Today!

Solutions Showcase

Explore some of our unique and creative solutions

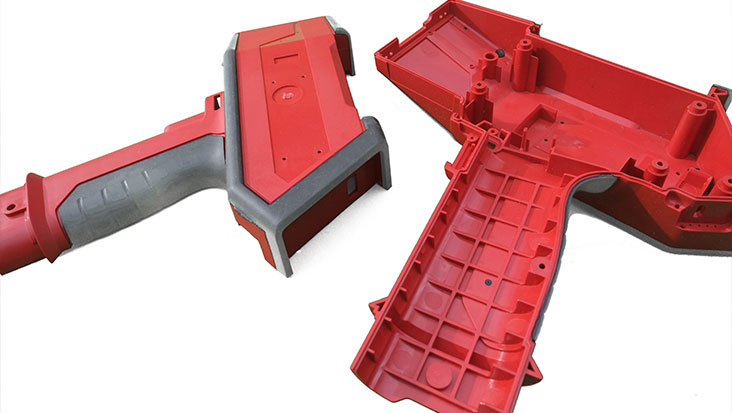

Two-Shot Overmolded Industrial Metal Analyzer: Precision Meets Durability

In the world of industrial tools, durability and functionality are paramount. One such product that embodies these qualities is an industrial metal analyzer, a handheld device that utilizes...

IP67-Rated Secondary Assembly for Bombardier Dashboard Speakers

In demanding environments where electronics are exposed to water, dust, and harsh conditions, IP67-rated waterproofing ensures durability and longevity. One such application...

IMD Medical Molding for Vivo 55 Ventilators & CPAP Machines

Medical devices demand precision, durability, and aesthetics that withstand sterilization and frequent use. The Vivo 55 ventilators and CPAP machines incorporate an advanced In-Mold...

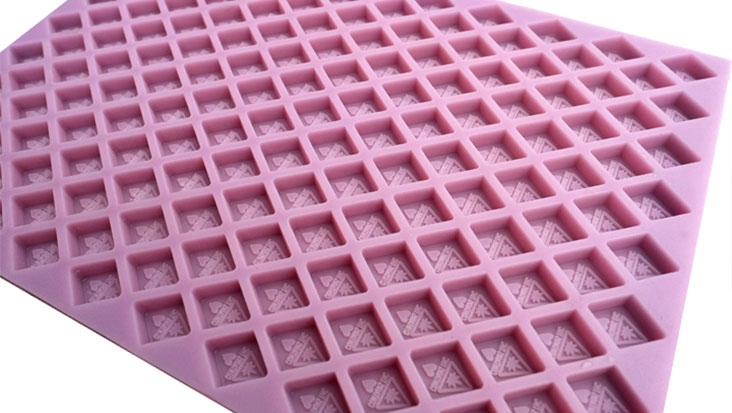

Precision-Made Gummy Pharmaceutical Molds for FDA-Approved Production

As the pharmaceutical and nutraceutical industries expand, precision molding plays a critical role in ensuring safe and consistent production of products like THC-infused gummies...

Turnkey Assembly

We have: Pad printing, silk screening, hot stamping, flow painting, UV printing, CNC gluing, CNC inserting, Ultrasonic welding with IP67, near net shape with precision CNC finishing of parts...

15 Minute Covid-19 Rapid Test Kit

Get peace of mind knowing your projects are backed by over 35 years of expertise. Since 1988, we've been committed to delivering seamless, end-to-end solutions tailored to your needs.

Book Your Free

Demonstration Today!

Imagine unlocking the full potential of your next big idea—faster than you thought possible.

In just one hour, we'll show you:

Groundbreaking innovations that redefine what's possible.

Unparalleled engineering expertise that sets the gold standard.

Tailored solutions that give you a competitive edge.

You'll leave with the confidence that your dream project is in the best hands.

Don't settle for ordinary—schedule your demonstration now and take the first step toward extraordinary results.