Injection Molding Capabilities

Press Sizes Up to 1,000 Tons

Suitable for everything from small precision parts to large, complex housings.

Low to Medium Volume Production Runs

Efficient for prototyping and production quantities without overseas delays.

Short-Run & Prototype Molding

Quickly validate your designs without committing to large-scale production.

In-House Toolmaking & Mold Design

Fast turnaround and full control of the mold lifecycle.

Plastic Component Assembly

Optional post-molding assembly to streamline your workflow.

CAD/CAM Integration

We work with industry-standard design tools for seamless collaboration.

Injection Molding Materials

We mold everything from rugged industrial components to sleek consumer products using a broad selection of thermoplastics tailored to your part's performance, durability, and appearance needs. Our commonly supported materials include:

ABS – Strong, impact-resistant, and easy to finish

Polycarbonate (PC) – Tough and clear with high heat resistance

Nylon (PA) – Durable and wear-resistant for mechanical parts

Polypropylene (PP) – Lightweight, chemical-resistant, and flexible

Polystyrene (PS) – Cost-effective and great for high-volume runs

Acetal (POM) – Low-friction and stable for precise engineering parts

TPE/TPU – Rubber-like elastomers for flexible or overmolded parts

High-Temp Resins (PPSU, PEI, etc.) – For demanding aerospace or medical use

And so much more

We ensure consistent performance across all materials with complete resin drying before and during molding—critical for strength, surface quality, and dimensional accuracy.

Not sure which resin is right for your part? Our engineers can help you select the ideal material.

More Information

All of our services are built from the ground up to meet your exact product requirements—flexible, in-house, and never one-size-fits-all

Full Range of Presses

A full range of press sizes up to 1,000 tons provides the capability of producing small to large parts.

Low to Medium Volume

Low to medium volume focus supports quick response to meet delivery requirements and part quality.

Complete Resin Drying

Complete drying of resins prior to and during the molding process provides consistent quality of material characteristics.

Technical Expertise

Technical expertise with a wide range of resins and injection molding experience provide the skill set required to serve a diverse customer base.

How We Work

Here's how we turn your ideas into precision parts

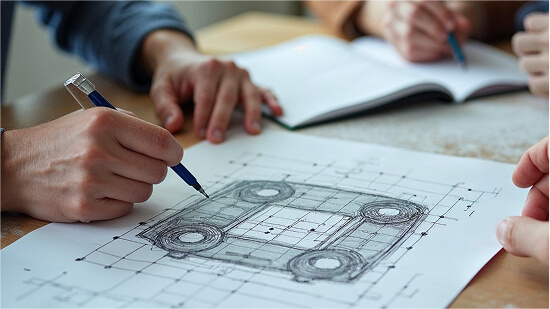

Consult & Design

We start by listening to your needs. Our team collaborates with you to design custom molds—single or multi-cavity—using advanced tools, ensuring every detail fits your vision.

Why Us? Personalized attention from our dedicated crew sets the stage for success.

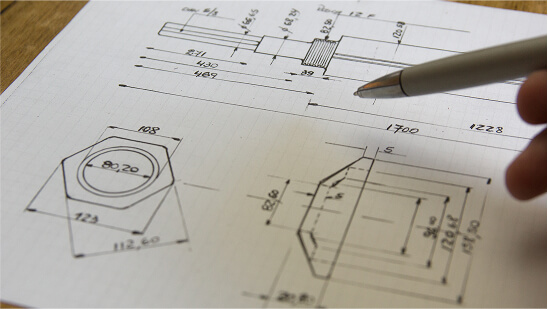

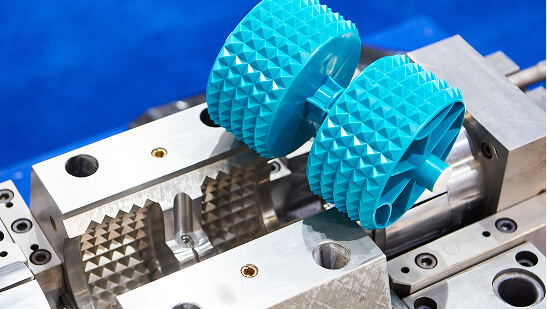

Build with Precision

Using state-of-the-art CNC machining and EDM tech, we craft your molds in-house. This means faster builds, tighter quality control, and parts that perform perfectly.

Why Us? Our cutting-edge equipment and expertise deliver unmatched precision and speed.

Mold & Produce

We bring your mold to life with our injection molding process, creating high-quality plastic parts tailored to your specs—whether it's one prototype or thousands of pieces.

Why Us? End-to-end service keeps everything seamless and on time.

Support & Refine

Need tweaks or repairs? We've got you covered with in-house mold maintenance and ongoing support to keep your production running smoothly.

Why Us? We go beyond delivery, ensuring your success long-term.

In summary, creating a high-quality mold isn't just about cutting steel—it's about precision, efficiency, and problem-solving. At Florida Custom Mold, the journey begins with expert engineering that transforms your idea into a functional design. Our team leverages decades of experience to craft molds that balance durability, speed, and cost-effectiveness. Whether you need a prototype to test your concept or a full-scale production mold, we tailor each solution to your unique needs. Advanced mold-making techniques ensure seamless functionality, while rigorous testing guarantees a reliable end product. From initial concept to final production, we prioritize efficiency and quality so your parts come out flawless every time.

Let's discuss your project today!

Book Your Free Demonstration Today!

Imagine unlocking the full potential of your next big idea—faster than you thought possible.

In just one hour, we'll show you:

Groundbreaking innovations that redefine what's possible.

Unparalleled engineering expertise that sets the gold standard.

Tailored solutions that give you a competitive edge.

You'll leave with the confidence that your dream project is in the best hands.

Don't settle for ordinary—schedule your demonstration now and take the first step toward extraordinary results.