Engineering Capabilities

From product idea to production-ready parts, we support your success every step of the way

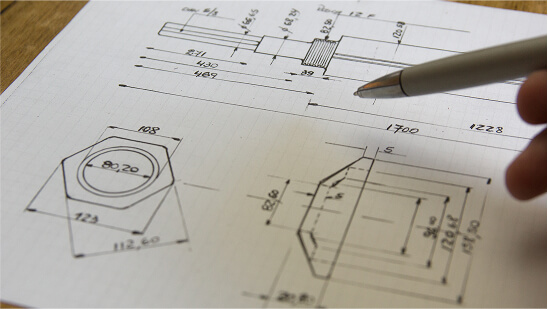

Design for Manufacturability (DFM)

Early collaboration helps reduce risk and speed up production. We evaluate your part design for moldability, material compatibility, wall thickness, draft angles, and more.

Rapid Prototyping & Validation

Bring your ideas to life quickly with functional prototypes. We help you test fit, form, and function—so you can move forward with confidence.

CAD/CAM Integration

We work with your native 3D files in SolidWorks, STEP, IGES, and more, converting them into precise tool paths for moldmaking and machining.

Mold Flow Analysis

Simulation tools help predict how materials will flow into your mold, reducing the risk of warping, sink marks, short shots, and other costly defects.

Engineering Change Support

Whether you're updating an existing design or scaling for production, we help implement engineering changes with minimal disruption and full documentation.

Collaborative Problem Solving

Need help refining a part or solving a tricky tolerance issue? Our engineers work directly with your team to improve outcomes at every step.

How We Work

We don't just manufacture—we collaborate. Our engineering support helps you design smarter, launch faster, and reduce production headaches. Whether you need early-stage consulting or last-mile design fixes, our team is here to help you move from idea to execution with clarity and speed

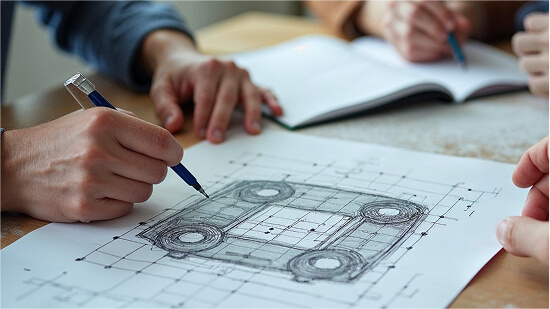

Consult & Design

We start by listening to your needs. Our team collaborates with you to design custom molds—single or multi-cavity—using advanced tools, ensuring every detail fits your vision.

Why Us? Personalized attention from our dedicated crew sets the stage for success.

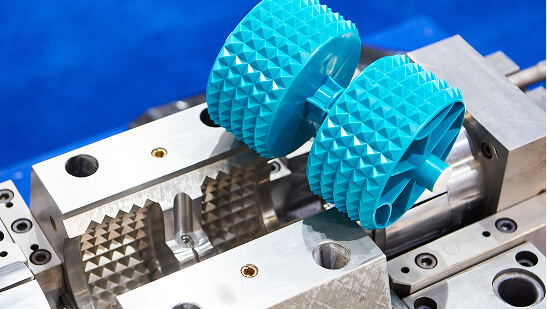

Build with Precision

Using state-of-the-art CNC machining and EDM tech, we craft your molds in-house. This means faster builds, tighter quality control, and parts that perform perfectly.

Why Us? Our cutting-edge equipment and expertise deliver unmatched precision and speed.

Mold & Produce

We bring your mold to life with our injection molding process, creating high-quality plastic parts tailored to your specs—whether it's one prototype or thousands of pieces.

Why Us? End-to-end service keeps everything seamless and on time.

Support & Refine

Need tweaks or repairs? We've got you covered with in-house mold maintenance and ongoing support to keep your production running smoothly.

Why Us? We go beyond delivery, ensuring your success long-term.

In summary, creating a high-quality mold isn't just about cutting steel—it's about precision, efficiency, and problem-solving. At Florida Custom Mold, the journey begins with expert engineering that transforms your idea into a functional design. Our team leverages decades of experience to craft molds that balance durability, speed, and cost-effectiveness. Whether you need a prototype to test your concept or a full-scale production mold, we tailor each solution to your unique needs. Advanced mold-making techniques ensure seamless functionality, while rigorous testing guarantees a reliable end product. From initial concept to final production, we prioritize efficiency and quality, so your parts come out flawless every time.

Let's Discuss Your Project Today!

Solutions Showcase

Explore real-world examples of how our engineering support helped clients overcome design challenges, reduce lead times, and achieve better product performance

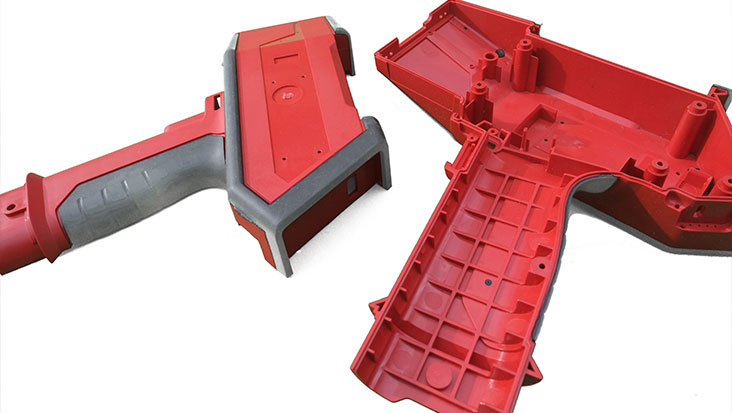

Two-Shot Overmolded Industrial Metal Analyzer: Precision Meets Durability

In the world of industrial tools, durability and functionality are paramount. One such product that embodies these qualities is an industrial metal analyzer, a handheld device that utilizes...

IP67-Rated Secondary Assembly for Bombardier Dashboard Speakers

In demanding environments where electronics are exposed to water, dust, and harsh conditions, IP67-rated waterproofing ensures durability and longevity. One such application...

IMD Medical Molding for Vivo 55 Ventilators & CPAP Machines

Medical devices demand precision, durability, and aesthetics that withstand sterilization and frequent use. The Vivo 55 ventilators and CPAP machines incorporate an advanced In-Mold...

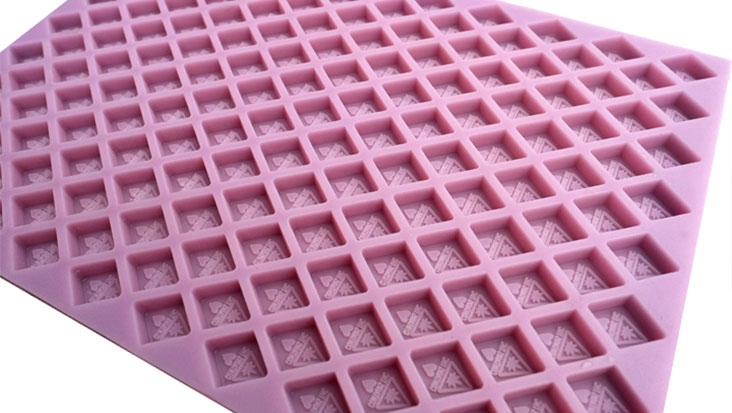

Precision-Made Gummy Pharmaceutical Molds for FDA-Approved Production

As the pharmaceutical and nutraceutical industries expand, precision molding plays a critical role in ensuring safe and consistent production of products like THC-infused gummies...

Turnkey Assembly

We have: Pad printing, silk screening, hot stamping, flow painting, UV printing, CNC gluing, CNC inserting, Ultrasonic welding with IP67, near net shape with precision CNC finishing of parts...

15 Minute Covid-19 Rapid Test Kit

Get peace of mind knowing your projects are backed by over 35 years of expertise. Since 1988, we've been committed to delivering seamless, end-to-end solutions tailored to your needs.

Book Your Free

Demonstration Today!

Schedule a virtual or in-person demo to see how our engineering, moldmaking, and production teams work together to bring your designs to life—faster and with greater accuracy.

In just one hour, we'll show you:

Groundbreaking innovations that redefine what's possible.

Unparalleled engineering expertise that sets the gold standard.

Tailored solutions that give you a competitive edge.

You'll leave with the confidence that your dream project is in the best hands.

Don't settle for ordinary—schedule your demonstration now and take the first step toward extraordinary results.